Plastic Flow Simulation

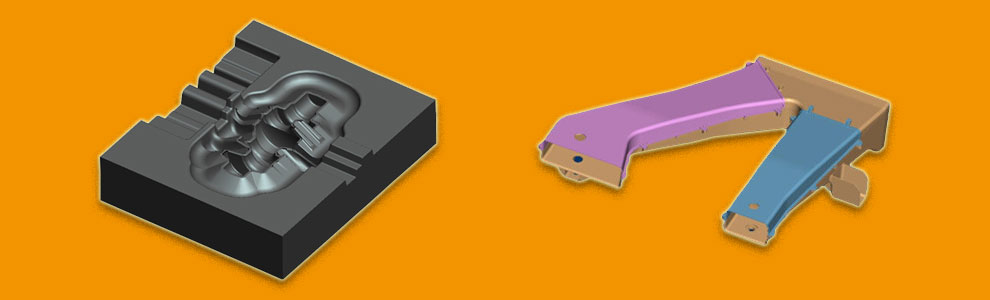

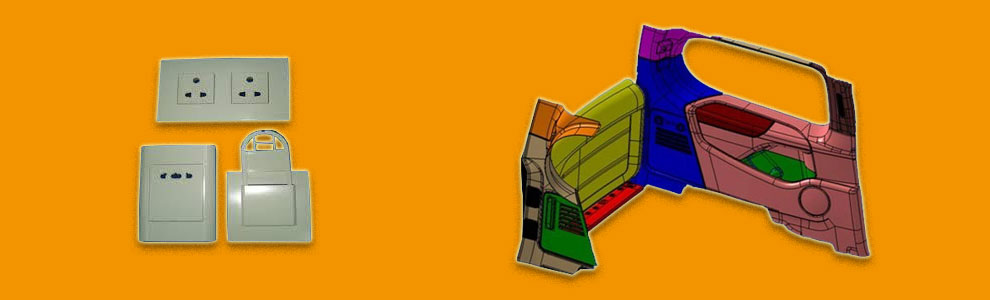

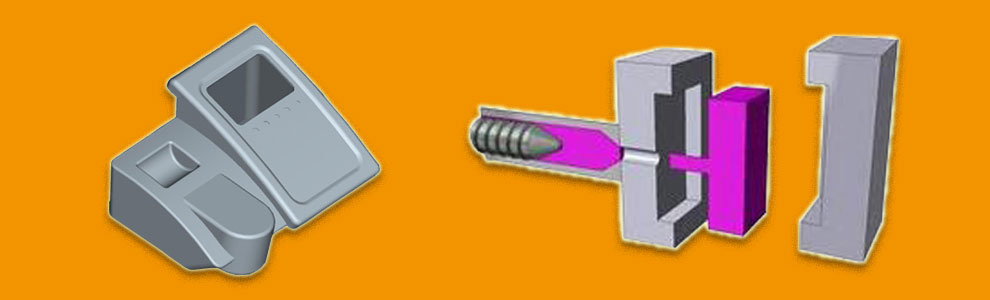

SolidWorks simulation professional helps ensure that your designs can be accurately and cost-efficiently manufactured by finding design errors on-screen-instead of on the production floor.

Compare and Optimize Alternatives : Determine the best design option by comparing strengths, life, cost, and weight. Perform all comparisons and design modifications within the SolidWorks environment.

Simulate Drop Test or Impact : Save time and cost by reducing the number of physical tests. Define drop height, surface, and orientation. Perform realistic collision simulation between parts or assemblies.

Predict Buckling or Collapse : Virtually apply forces, pressure, gravity, and centrifugal forces to your designs to determine maximum loads before buckling. Study the effects of various materials as well as isotopic and orthotropic factors.

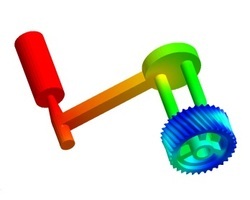

Simulate Heating or Cooling : Thermal analysis capabilities enable you to easily study heat effects on your designs. Simulate thermal boundary conditions, fluid flow, thermal-structural interactions, and radiation effects in high-temperature applications.